Why choose a high-pressure compressor from Laco Air Solutions?

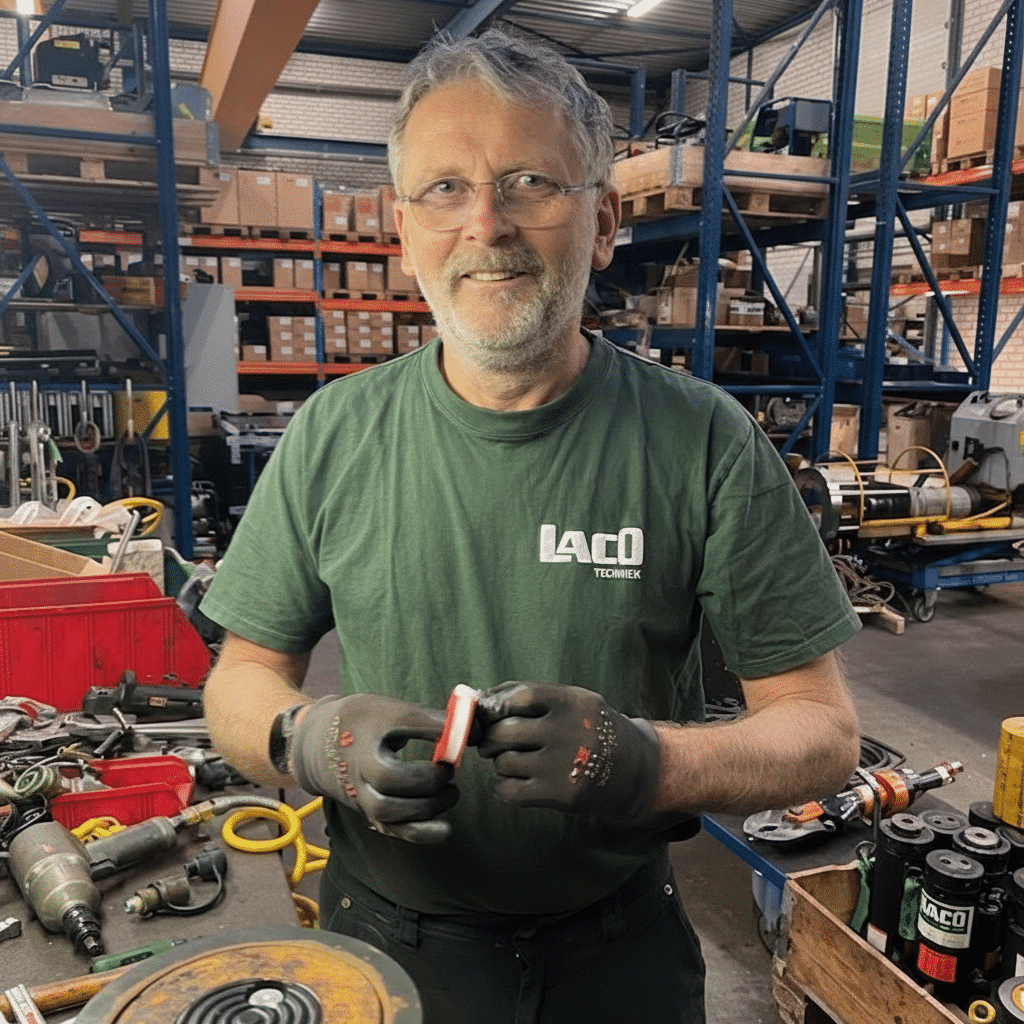

At Laco Techniek, you’re not only choosing a powerful high-pressure compressor, but also reliability, customization, and expert support. With over 80 years of experience in industrial applications, our specialists know exactly which machines perform under the toughest conditions. Whether it’s temporary rental or a long-term investment, we’ll work with you and deliver exactly what your project needs.

At Laco, you benefit from:

- Fast delivery and flexible rental or purchase options

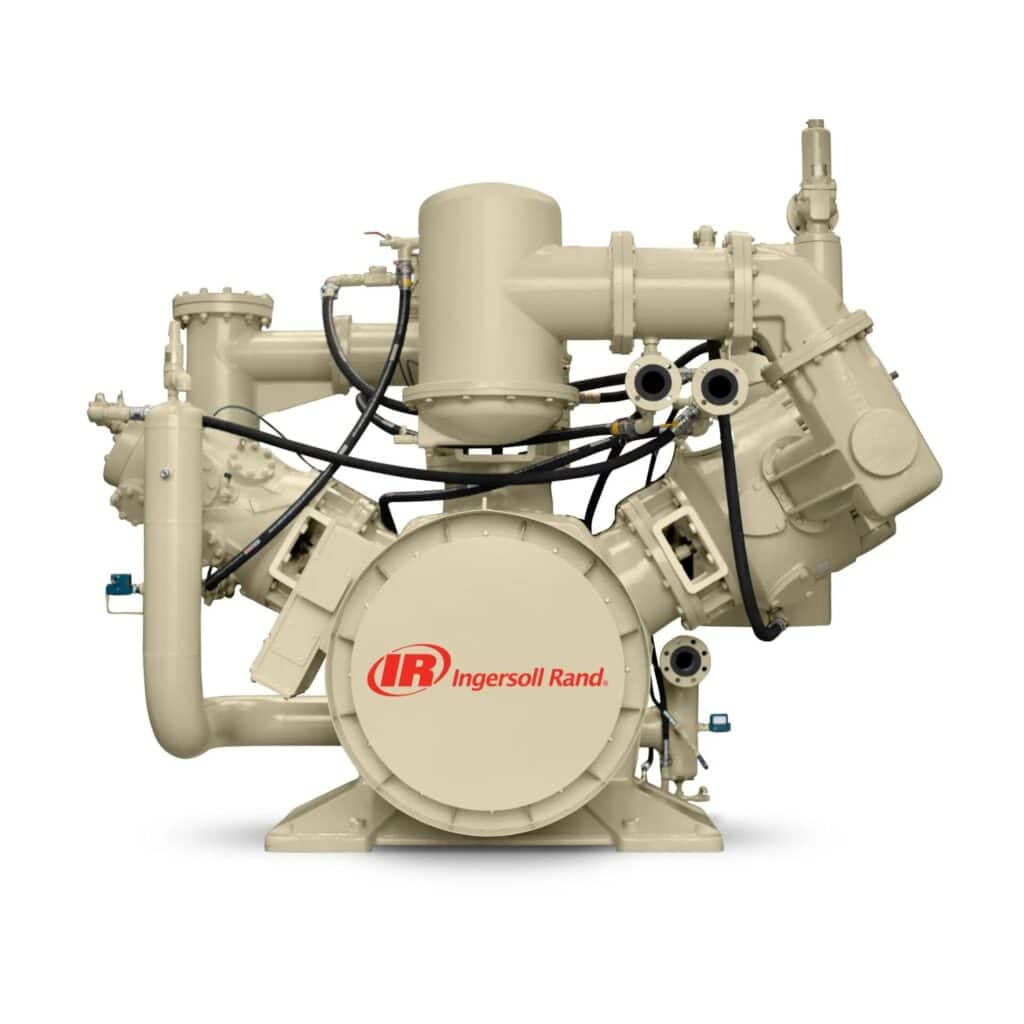

- A wide range of premium brands such as Ingersoll Rand, Atlas Copco, and Boge

- Tailored technical advice, even for complex applications

- Service and maintenance by experienced technicians

- 24/7 availability for emergencies

Laco Air Solutions is the ideal partner for companies in offshore, shipbuilding, (petro)chemical, and heavy industry. Ready to work with a compressor that truly delivers what you need?