About calibrating torque wrenches

Torque wrenches and other screw tools must operate within strict tolerances to deliver the correct force—the torque—to tighten bolts or nuts according to specifications. Too great a deviation can result in a less reliable or vulnerable bolt connection. That is why torque wrenches must be calibrated at least once a year, which means they are tested for accuracy. You can do this yourself by renting or purchasing reading and measuring equipment, but for high-quality machines, it is advisable to leave the calibration to Laco, the specialist.

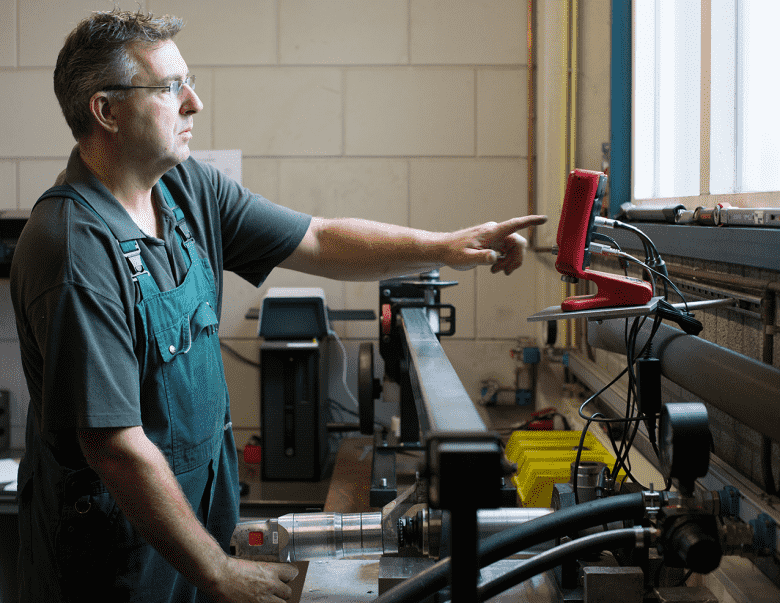

Calibration of tools in practice at Laco

We always combine the testing of torque tools with preventive maintenance and, if necessary, repairs. Calibration of torque wrenches includes the following activities:

- Visual inspection of the torque tool

- Repair and maintenance of the torque tool

- Cleaning and inspection of the internal parts

- Re-greasing of rotating parts

- Calibrating torque tools on the test unit.

Once the tool has been calibrated by us, you will receive a digital calibration certificate from us.

Calibration equipment

We have advanced testing equipment for virtually all types of screw tools and power amplifiers. Our measuring and reading equipment can handle all common capacities. The torque testers are operated by experienced service staff with expert knowledge. This means you can rest assured that your machines are correctly adjusted and that the continuity of your production process is not at risk.

Which brands do we offer?

View the brands we offer within this product group here

Questions? Feel free to contact us.